Take these steps to enhance your supply chain analytics

Running a successful business is all about making the most of your resources. And when it comes to resources, few are as important as your supply chain.

Your supply chain is responsible for getting goods and materials to your business in a timely and efficient manner. This can be a challenge, especially if you’re not taking advantage of supply chain analytics.

In the world of business, supply chain analytics is a critical component of success. By optimizing your supply chain, you can drive revenue and increase productivity. This includes utilizing the latest technological trends while ensuring that your processes are as efficient as possible.

In this article, we will take a look at four steps you can take to enhance your supply chain analytics.

Defining supply chain analytics

Before we can discuss how to improve supply chain analytics, we need to first define what it is.

Supply chain analytics is the process of using data and analytical methods to optimize the supply chain. This includes improving planning and execution, as well as reducing waste and inventory.

It’s important to note that supply chain analytics is not just about using data to make decisions. It’s also about understanding the data itself and being able to use it to improve decision-making.

Improving planning and execution

The first step in enhancing your supply chain analytics is improving planning and execution. This includes developing a clear plan for your supply chain and ensuring that everyone involved understands it.

It’s also important to have a system in place for tracking progress and ensuring that everyone is meeting their deadlines.

In addition, you need to be able to adapt quickly to changes in the market. This means being able to make decisions quickly and adjusting your plans as needed.

Applying analytics to planning and execution

A company is planning to release a new product. The product is expected to be popular, so the company decides to increase production. However, due to a delay in production, the company ends up running out of stock and misses the peak sales season.

If the company had been using supply chain analytics, they would have been able to predict the delay and adjust their plans accordingly. This would have prevented them from running out of stock and losing revenue.

Reducing waste and inventory

The second step in enhancing your supply chain analytics is reducing waste and inventory. This includes minimizing the amount of wasted time, materials, and money.

It’s also important to have an accurate inventory tracking system so you can keep track of what you have and what you need.

Applying analytics to waste and inventory

A company is ordering materials for a new product. However, they order too much of the materials and end up with a lot of leftover stock.

If the company had been using supply chain analytics, they would have been able to predict how much material they would need and order the correct amount. This would have saved them money on unnecessary inventory.

Utilizing technology

The third step in enhancing your supply chain analytics is utilizing technology. This includes using the latest software and tools to improve planning and execution.

It’s also important to use data mining and analysis tools to help you understand the data you’re gathering. This means you can make better decisions based on accurate information.

Leveraging technology for analytics

A company is using an outdated inventory system. As a result, they are ordering more materials than they need and wasting money on unnecessary stock.

If the company had been using supply chain analytics, they would have been able to upgrade their inventory system and save money in the process. By using the latest technology, they would have been able to make better decisions based on accurate data.

Building a team of analysts

The fourth and final step in enhancing your supply chain analytics is building a team of analysts. This includes hiring individuals with the skills and knowledge necessary to analyze data and make sound decisions.

It’s also important to train your team members so they understand how to use the data to improve the supply chain.

Data analysts improve business processes

A company is having trouble meeting deadlines. As a result, they decide to hire a team of analysts to help them improve their planning and execution.

If the company had been using supply chain analytics, they would have been able to identify this problem and hire a team of analysts to help them. By using data analysis, the team would be able to improve planning and execution and meet deadlines.

Using technology to enhance supply chain analytics

It’s no secret that technology has had a profound impact on supply chain management. In fact, many experts believe that technology is the key to success for modern businesses.

There are several reasons for this:

1. Technology allows businesses to gather and analyze data quickly and easily. This means they can make better decisions based on accurate information.

2. Technology enables businesses to connect with suppliers and customers around the world. This allows them to collaborate more effectively and create a global supply chain.

3. Technology makes it easier for businesses to manage their inventory and operations. This helps them reduce waste and improve efficiency.

4. Technology allows businesses to track customer behavior and preferences. This helps them design products that meet customer needs and expectations.

5. Technology provides businesses with the tools they need to compete in a global marketplace.

When it comes to supply chain analytics, technology is your friend! By using the latest software and tools, you can improve planning and execution. You can also use data mining and analysis tools to understand the data you’re gathering. This means you can make better decisions based on accurate information.

What technology should I use?

When it comes to supply chain analytics, there are several types of technology you can use. Here are some of the most common:

1. Enterprise resource planning (ERP) software: ERP software is designed to manage resources and operations. It helps businesses track inventory, sales, and other key metrics.

2. Supply chain management (SCM) software: SCM software helps businesses plan, execute, and optimize their supply chain. It allows businesses to connect with suppliers and customers around the world.

3. Data mining and analysis tools: Data mining and analysis tools allow businesses to understand the data they’re gathering. This helps them make better decisions based on accurate information.

4. Business intelligence (BI) software: BI software allows businesses to track customer behavior and preferences. It also provides businesses with the tools they need to compete in a global marketplace.

4. Manufacturing execution system (MES) software: MES software helps businesses manage their manufacturing process. It allows businesses to track production, quality, and other key metrics.

5. Warehouse management system (WMS) software: WMS software helps businesses manage their warehouse operations. It allows businesses to track inventory, shipping, and other key metrics.

6. Customer relationship management (CRM) software: CRM software helps businesses manage their customer relationships. It allows businesses to track customer data, preferences, and behavior.

7. Transportation management system (TMS) software: TMS software helps businesses manage their transportation process. It allows businesses to track shipping, routes, and other key metrics.

Choosing the right technology

When it comes to supply chain analytics, it’s important to choose the right technology. Not all technology is created equal, and some technologies are better suited for certain businesses than others.

Here are some tips for choosing the right technology:

1. Do your research: Before you make any decisions, it’s important to do your research. Learn about the different types of technology and what each one can do for your business.

2. Talk to experts: Talk to experts in the field and ask them for their advice. They can help you find the right technology for your business.

3. Try before you buy: Many software vendors offer trial versions of their software. This allows you to try out the software before you buy it.

4. Ask for help: If you’re not sure what technology is right for you, ask for help. There are many experts out there who can help you find the right technology for your business.

5. Be patient: It can take time to find the right technology for your business. Don’t rush into anything and take the time to do your research.

The bottom line

Technology is an important part of supply chain analytics.

By using the latest software and tools, you can improve planning and execution. You can also use BI tools to understand the data you’re gathering. This means you can make better decisions based on accurate information.

When your business has the ability to harness the power of data analytics and put it into action, it unlocks the ability to make significant improvements to your bottom line. With supply chain analytics, you can:

- Reduce inventory costs

- Improve product quality

- Streamline production processes

- Enhance customer service

- Optimize shipping and transportation processes

The possibilities are endless! Supply chain analytics is one of the most important things to consider when it comes to running a successful business. It’s imperative that you optimize your supply chain in order to drive revenue and increase productivity.

Check out some related resources:

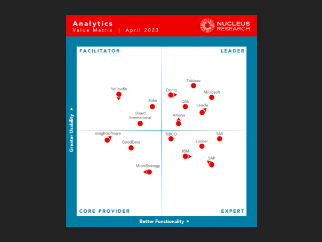

Domo Named a Leader in Nucleus Research’s 2023 Analytics Technology Value Matrix

Data-Driven Decisions Are Both Science and Art